Equipment

(1) Browne & Sharpe Global Classic CMM with calibration records

- PCDIMIS software

- programmable head with 1 degree increment capabilities

- 700mm x 1000mm x 700mm work envelope

- 10 probing tips changing station

- full scanning capable

- able to program from solid models/check back to models

(1) Browne & Sharpe Global S CMM with calibration records

- PCDIMIS software

- programmable head with 1 degree increment capabilities

- 500mm x 700mm x 500mm work envelope

- 10 probing tips changing station

- full scanning capable

- able to program from solid models/check back to models

(1) Fowler Trimos V3 height gage with calibration records

- PCDIMIS software

- programmable head with 1 degree increment capabilities

- 700mm x 1000mm x 700mm work envelope

- 10 probing tips changing station

- full scanning capable

- able to program from solid models/check back to models

(1) Okuma MB4000H with Hydraulic fixture capability and Halter CNC robot load assist

(2) Okuma MB4000H Horizontal Machining Centers

- 110 tool automatic tool changer

- through spindle high pressure coolant 1000 psi

- working envelope X: 22.05, Y: 22.05, Z: 24.6

- .001 Degree B Axis Rotary Table

- 15,000 RPM spindle

- Auto Gauging by Renishaw

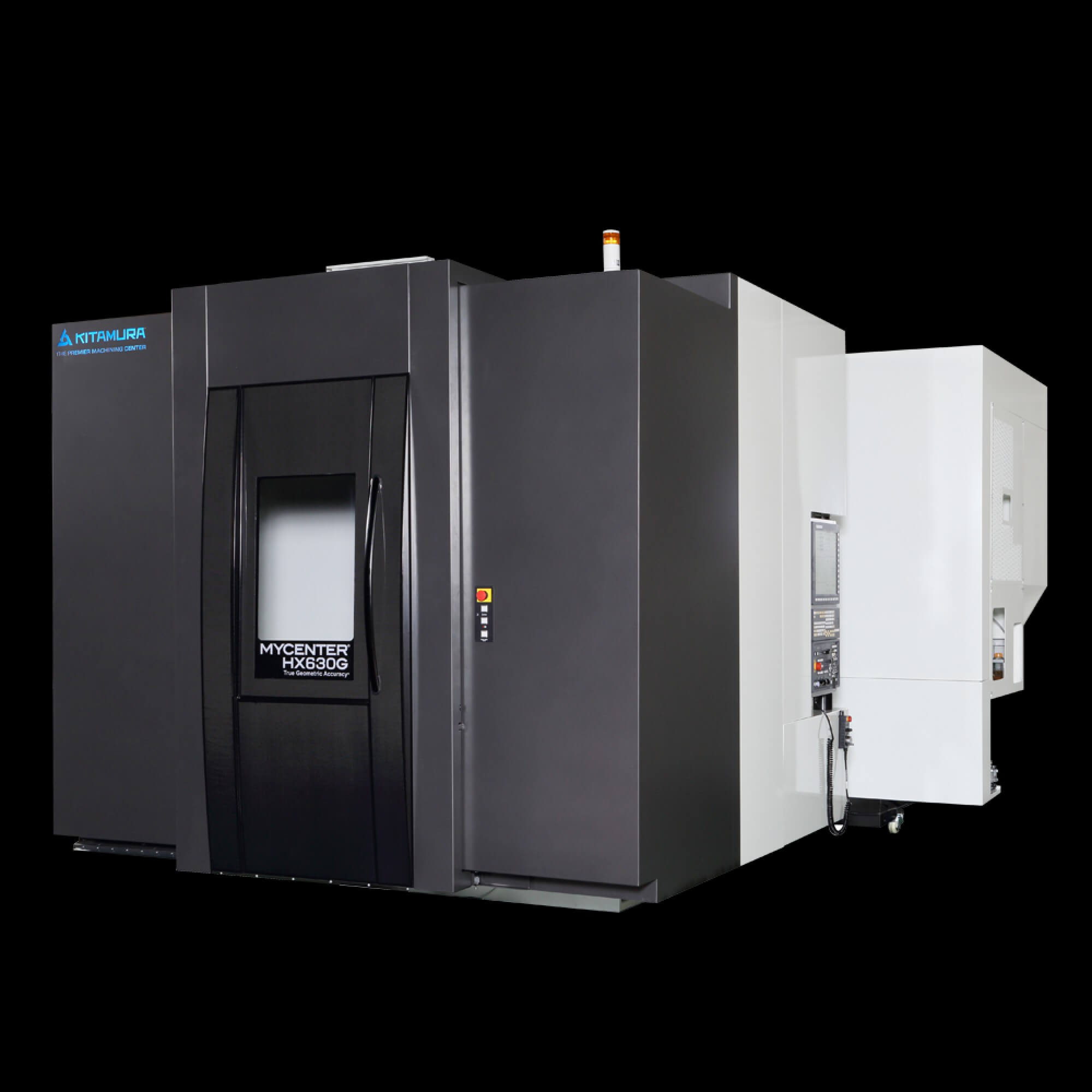

(1) Kitamura Mycenter HX630 Horizontal Machining Center Full 5 Axis

- 50 tool automatic tool changer

- through spindle high pressure coolant 1000 psi

- working envelope X: 43.3, Y: 36.2, Z: 41.3

- .001 Degree B Axis Rotary Table

- 12,000 RPM spindle

- Auto Gauging by Renishaw

(1) Kitamura Mycenter HX250 Horizontal Machining Center 10 Pallet Automatic Changer

- 100 tool automatic tool changer

- through spindle high pressure coolant 1000 psi

- working envelope X: 12.0, Y: 12.0, Z: 13.0

- .001 Degree B Axis Rotary Table

- 15,000 RPM spindle

- 10 pallet auto changer so your parts stay setup and ready to run

(1) Kitamura Mycenter HX250 Horizontal Machining Center

- 50 tool automatic tool changer

- through spindle high pressure coolant 1000 psi

- working envelope X: 12.0, Y: 12.0, Z: 13.0

- 15,000 RPM spindle

- .001 Degree B Axis Rotary Table

(2) Kitamura 4xid Vertical Machining Center 4th Axis Capable

- 40 tool automatic tool changer

- through spindle high pressure coolant 1000 psi

- working envelope X: 40.0, Y: 40.0, Z: 20.1

- 12,000 RPM spindle

- .001 Degree B Axis Rotary indexer

- Auto Gauging by Renishaw

(2) Kitamura Sparkchanger 2 Station Automatic Pallet Vertical Machining Center 4th Axis Capable

- 40 tool automatic tool changer

- through spindle high pressure coolant 1000 psi

- working envelope X: 23.6, Y: 20.1, Z: 20.1

- 12,000 RPM spindle

- .001 Degree B Axis Rotary indexer capable

- Auto Gauging by Renishaw

(1) Okuma MV560 Vertical Machining Center 4th Axis Capable

- 30 tool automatic tool changer

- through spindle high pressure coolant 1000 psi

- working envelope X: 41.34, Y: 22.05, Z: 18.11

- 15,000 RPM spindle

- .001 Degree B Axis Rotary indexer capable

- Auto Gauging by Renishaw

(2) Bridgeport GX1000 OSP Vertical Machining Center 4th Axis Capable

- 30 tool automatic tool changer

- through spindle high pressure coolant 1000 psi

- working envelope X: 41.34, Y: 22.05, Z: 18.11

- 10,000 RPM spindle

- .001 Degree B Axis Rotary indexer capable

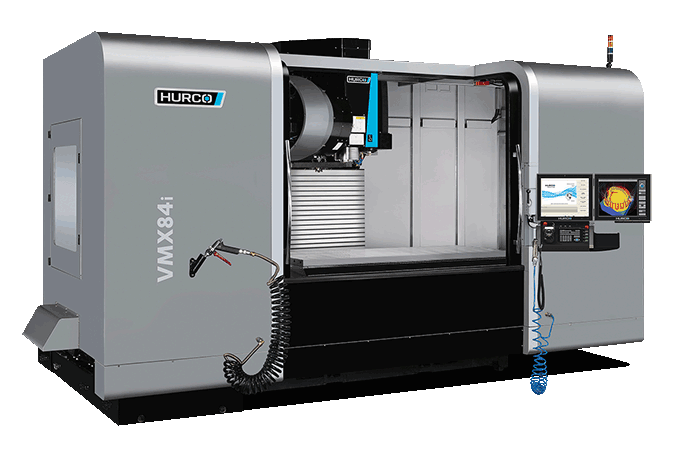

(1) Hurco VMX84i Vertical Machining Center 4th Axis Capable

- 40 tool automatic tool changer

- through spindle high pressure coolant 1000 psi

- working envelope X: 84, Y: 34, Z: 30

- 15,000 RPM spindle

- .001 Degree B Axis Rotary indexer capable

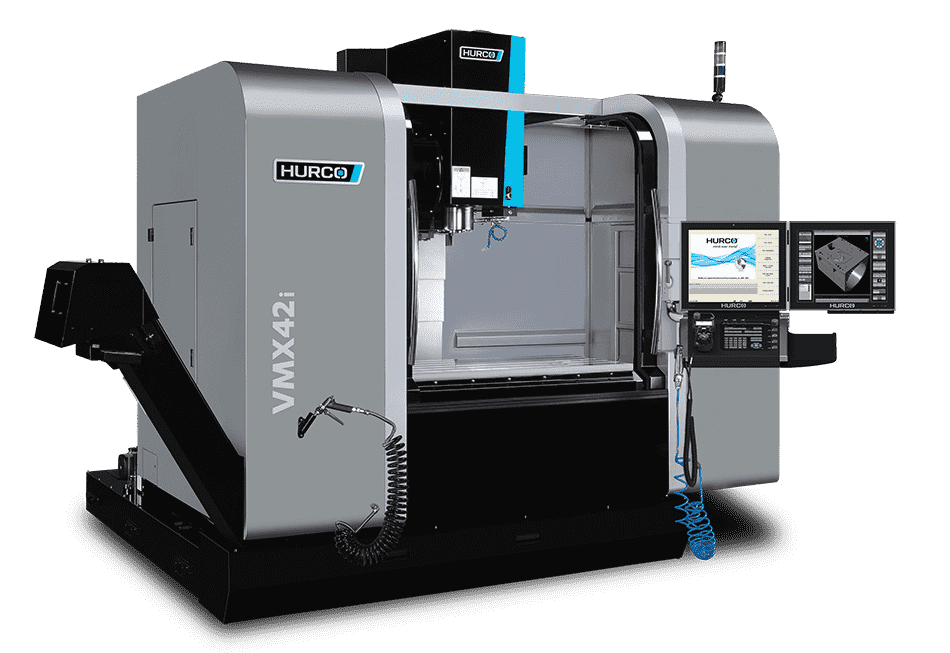

(1) Hurco VMX42i Vertical Machining Center

- 40 tool automatic tool changer

- working envelope X: 42, Y: 24, Z: 24

- 15,000 RPM spindle

(1) Okuma LT3000 EX

(1) Okuma LB3000EXBB- MYW/800 with Live Tooling and 72 inch Bar Feeder Capabilities

- 12/24 station turret

- 10 inch main spindle

- 6 inch sub spindle

- through turret high pressure coolant 300 psi

- max turn diameter 14.5 inches

- travels 19.5 inches

- 4,200 RPM main spindle

- 6,000 rpm sub spindle

- .001 Degree C Axis Rotary milling indexer capable

- 72 inch bar feeder for high volume parts

(1) Okuma Genos L300- M-E with Live Tooling and 72 inch Bar Feeder Capabilities

- 12/24 station turret

- collet chuck main spindle

- 6 inch sub spindle

- through turret high pressure coolant 300 psi

- max turn diameter 14.5 inches

- travels 19.5 inches

- 6,000 RPM main spindle

- 6,000 rpm sub spindle

- .001 Degree C Axis Rotary milling indexer capable

- 72 inch bar feeder for high volume parts

(3) Okuma LB3000EXBB/500

- 12 station turret

- 12 inch main spindle

- through turret high pressure coolant 300 psi

- max turn diameter 15 3/4 inches

- travels 19.5 inches

- 4,200 RPM main spindle

- big bore 3.15 thru the spindle

- programmable tailstock

(1) Nakamura-Tome AS200-L with Live Tooling and 72 inch Bar Feeder Capabilities

- 12/24 station turret

- 10 inch main spindle

- 6 inch sub spindle

- through turret high pressure coolant 300 psi

- max turn diameter 12.5 inches

- travels 15.5 inches

- 5,000 RPM main spindle

- 6,000 rpm sub spindle

- .001 Degree C Axis Rotary milling indexer capable

- 72 inch bar feeder for high volume parts

(1) Nakamura-Tome SC300 II with Live Tooling and Halter Load Assist Robot

- 12/24 station turret

- 12 inch main spindle

- 8 inch sub spindle

- through turret high pressure coolant 300 psi

- max turn diameter 16.5 inches

- travels 19.5 inches

- 5,000 RPM main spindle

- 6,000 rpm sub spindle

- .001 Degree C Axis Rotary milling indexer capable

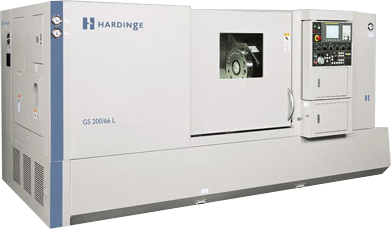

(1) Hardinge GS200L

- 12 station turret

- 8 inch main spindle

- through turret high pressure coolant 300 psi

- max turn diameter 13.5 inches

- travels 42 inches

- 5000 RPM main spindle

- manual tailstock

(1) Okuma LB3000 EXMYW/400 with Halter CNC robot load assist

(1) Yama Seiki GTZ-2600Y with Halter CNC robot load assist

(1) Super Tec EGI-150 CNC I.D. grinder with Halter CNC robot load assist

(8) Halter Load Assist Robotic Loader with 11 Stations

(1) Fanuc CRX

(8) Seats of Latest Version of Mastercam 5 Axis Capable

(1) Latest Version of Solidworks

(3) LNS Quick Six S2 Bar Feeders

- capable of holding 8 bars of material up to 3 inch diameter 6 feet long

- will also hold square,hex, or custom extrusions bars up to 6 feet long

(1) Devlieg Jig Mill

- work envelope X: 72, Y: 48, Z: 16

- Saddle travel 18

(1) Surface Grinder

- work envelope X: 18.0, Y: 12.0, Z: 6.0

- Saddle travel 18

(1) Mitsubishi FX10K Wire EDM

- work envelope X: 10, Y: 10, Z: 6